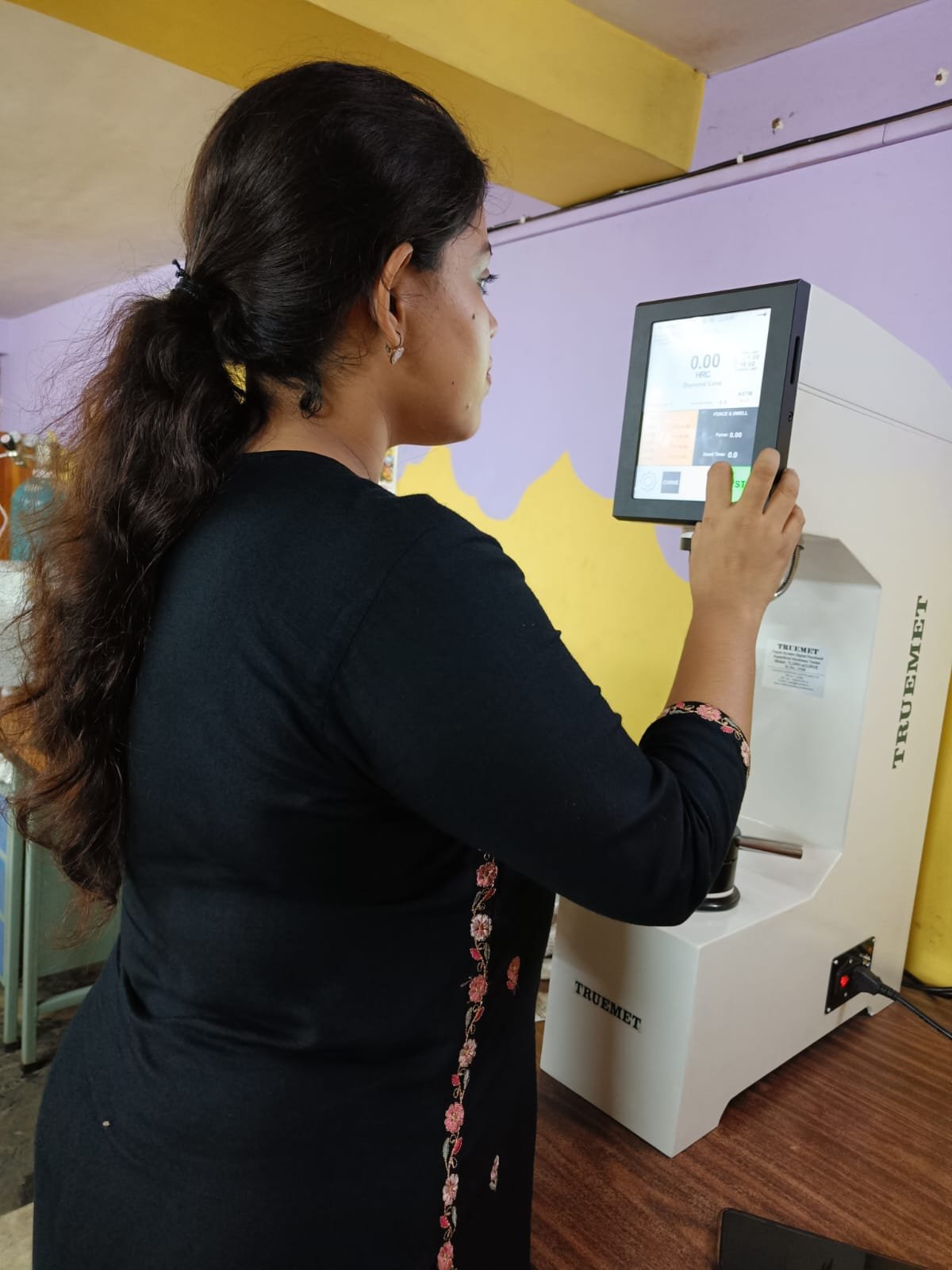

Chemical Testing

Chemical analysis is done using the German Made Optical emission

spectrometer - SPECTROMAXX - The Metal Analyzer of Choice - Worldwide. Optical

emission spectrometer provides the analysis of the chemical elements at the

complete range from sub-ppm to percentage levels, from pure metals trace analysis

to high alloyed grades. All relevant elements can directly be analyzed simultaneously.

SPECTROMAXX analyses Nitrogen levels in Carbon and Low Alloy Steel

from 10 PPM to 150 PPM and in Stainless Steel from 200 PPM to 700 PPM. The robustness

of the metal spectrometer allows the operation in all relevant situations for process

and quality control, incoming materials inspection, alloy identification and research

and certification. It can analyze any metal in any shape and form.

The German Optical Emission Spectrometer can analyse all elements

in Carbon Steel, Low Alloy Steel, Stainless Steel, High Speed Steel, Tool Steel,

Copper and its alloys and Aluminum and its alloys.

Featuers of OES

Stable and reliable technology.

Broad range of metals analysis.

Complete analysis in 45 seconds.

Relative Precision of about 1-3%.

Ultra-fast inclusion analysis capability.

Detection of rare or large inclusions.

Highly advanced software technology.

Unmatched technique for fast analysis.

Fastest analysis of all the elements with high precision and accuracy.

Analysis of the elements simultaneously Analysis of Metals in any shape and form.

Determines percentage of Nitrogen levels Ranges from trace (ppm) to alloy concentration levels.